Welding and Joining Technology

settingsFuel industry. Forge opportunity. Shape your future.

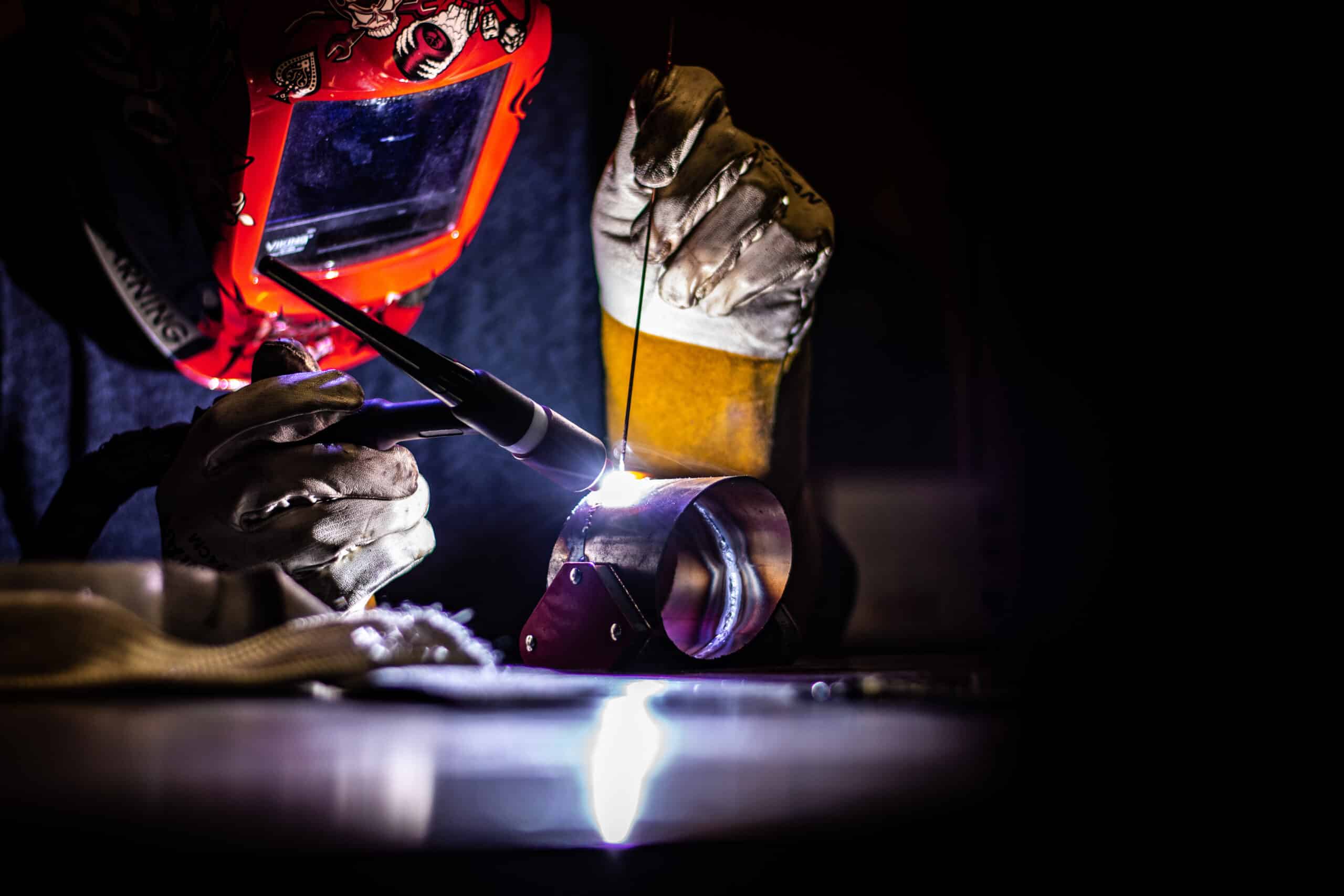

Welders are in high demand across diverse industries—building everything from ships and aircraft to skyscrapers, bridges, and power plants. With specialized skills, welders play a critical role in manufacturing, construction, automotive, aerospace, and more.

Overview

Welding is the primary method of permanently joining metal parts by melting and fusing them together using heat. It’s a skill-driven trade that requires precision, technique, and adaptability. Welders may work in a variety of environments—outdoors in all weather conditions or indoors in confined spaces designed to contain sparks and glare.

The complexity of the work can vary depending on:

- The position of the weld (horizontal, vertical, overhead, or 6G pipe welding)

- The types of metals being fused

- The specific requirements of each industry

Welders often work full time—many clock overtime hours—with about 1 in 5 welders working 50+ hours per week.

OFTC’s Welding and Joining Technology program offers hands-on training in a variety of welding techniques and processes, equipping students with the skills needed to succeed in the welding profession. Graduates are prepared to enter the workforce in high-demand fields such as:

- Construction

- Engineering

- Automotive repair and fabrication

- Aerospace manufacturing

- Industrial and manufacturing sectors

Program Length

Programs in the Welding & Joining Technology department can be completed in 1–5 semesters.

Programs

Advanced Shielded Metal Arc Welder Technical Certificates of Credit

Welding and Joining Technology

Certificate of Credit

1 Semester

The Advanced Shielded Metal Arc Welder Technical Certificate of Credit is a continuation of the basic certificate. The advanced program provides instruction in shielded metal arc welding in the overhead, horizontal, and vertical positions.

The HOPE Career Grant is available to HOPE Grant-qualified students who enroll in select majors specifically aligned with industries in which there are more jobs available in Georgia than there are skilled workers to fill them. Learn More

Basic Shielded Metal Arc Welder Technical Certificate of Credit

Welding and Joining Technology

Certificate of Credit

1 Semester

The Basic Shielded Metal Arc Welder Technical Certificate of Credit prepares students for careers in the welding and joining industry. This certificate emphasizes arc welding in the flat position and is pre-requisite to the advanced certificate.

The HOPE Career Grant is available to HOPE Grant-qualified students who enroll in select majors specifically aligned with industries in which there are more jobs available in Georgia than there are skilled workers to fill them. Learn More

Flux Cored Arc Welder Technical Certificate of Credit

Welding and Joining Technology

Certificate of Credit

1 Semester

The Flux Cored Arc Welder Technical Certificate of Credit introduces students to and provides instruction in flux cored arc welding practices. Topics include an introduction to the welding industry, oxyfuel cutting techniques, and flux cored arc welding practices.

The HOPE Career Grant is available to HOPE Grant-qualified students who enroll in select majors specifically aligned with industries in which there are more jobs available in Georgia than there are skilled workers to fill them. Learn More

Gas Metal Arc Welder Technical Certificate of Credit

Welding and Joining Technology

Certificate of Credit

1 Semester

The Gas Metal Arc Welder (GMAW) Technical Certificate of Credit prepares students for welding careers using the GMAW process. Topics include an introduction to welding technology, oxyfuel cutting techniques, and GMAW welding techniques and processes.

The HOPE Career Grant is available to HOPE Grant-qualified students who enroll in select majors specifically aligned with industries in which there are more jobs available in Georgia than there are skilled workers to fill them. Learn More

Gas Tungsten Arc Welder Technical Certificate of Credit

Welding and Joining Technology

Certificate of Credit

1 Semester

The Gas Tungsten Arc Welder (GTAW) Technical Certificate of Credit provides instruction in GTAW techniques. Topics include understanding the nature and culture of the welding industry, oxyfuel cutting techniques, and GTAW setup and operation and GTAW manipulation techniques.

The HOPE Career Grant is available to HOPE Grant-qualified students who enroll in select majors specifically aligned with industries in which there are more jobs available in Georgia than there are skilled workers to fill them. Learn More

Interdisciplinary Studies – Welding and Joining Technology Associate of Applied Science Degree

Welding and Joining Technology

Associate of Applied Science Degree

3 Semesters

The Associates of Applied Science Degree in Welding and Joining Technology program is designed to prepare students for careers in the welding industry. The program emphasizes welding theory and practical applications necessary for successful employment. Program graduates receive an Interdisciplinary Studies – Welding and Joining Technology degree, have the qualifications of a welding and joining technician, and are prepared to take qualification tests.

Pipe Shielded Metal Arc Welding Technical Certificate of Credit

Welding and Joining Technology

Certificate of Credit

2 Semesters

The Pipe Shielded Metal Arc Welding Technical Certificate of Credit program provides instruction in the theory and skills necessary to secure entry level employment in the pipe welding industry. Areas of instruction include an introduction to welding technology, mathematics, oxyfuel cutting, shielded metal arc welding, advanced shielded metal arc welding, preparation for industrial qualification and pipe welding.

The HOPE Career Grant is available to HOPE Grant-qualified students who enroll in select majors specifically aligned with industries in which there are more jobs available in Georgia than there are skilled workers to fill them. Learn More

Pipe Welder Technical Certificate of Credit

Welding and Joining Technology

Certificate of Credit

1 Semester

The Pipe Welder Technical Certificate of Credit program provides instruction in the specialized field of pipe welding. A good understanding and skill base is essential for the completion of this program. Topics include advanced gas tungsten arc welding practices, fabrication practices, and pipe welding techniques.

The HOPE Career Grant is available to HOPE Grant-qualified students who enroll in select majors specifically aligned with industries in which there are more jobs available in Georgia than there are skilled workers to fill them. Learn More

Welding and Joining Technology Diploma

Welding and Joining Technology

Diploma

4 Semesters

The Welding and Joining Technology diploma program is designed to prepare students for careers in the welding industry. Program graduates receive a Welding and Joining Technology diploma, have the qualifications of a welding and joining technician, and are prepared to take qualification tests.

The HOPE Career Grant is available to HOPE Grant-qualified students who enroll in select majors specifically aligned with industries in which there are more jobs available in Georgia than there are skilled workers to fill them. Learn More

Features

Job Stability & Security

Job growth in this industry is anticipated to continue, but welders who possess competency in the latest technologies or who do not mind relocating are likely to see the best job prospects.

Staying abreast with the newest developments and technology is important in any field, but especially in technical industries. This will improve your chances of getting ahead in your welding career.

Little or No Cost to You

With the Pell Grant, Georgia’s HOPE Grant, HOPE Scholarship, and HOPE Career Grant (for students/programs who qualify) and other scholarship opportunities, many students graduate OFTC with little to no debt.

Tuition & Fees

With tuition at $107 per credit hour, total costs for Welding & Joining Technology department programs range from:

- Tuition & Fees*: $1,532.00 – $7,043.00

- Books & Supplies*: $100.00 – $500.00

*Visit the OFTC Catalog to view each individual program and its full breakdown of tuition, fees, books, and supplies. Costs are estimated and are subject to change.

Advancement Opportunities

If you work hard and perform on the job, you may have the opportunity to advance to become a supervisor, instructor, technician or inspector.

As the construction industry looks to recruit the next generation of welders, big demand means more work, and with more work comes more opportunity. And as you progress in the craft, the more opportunities there are to climb the ladder and earn a higher income.

Locations

Oconee Fall Line Technical College has campuses throughout its 11-county service area. We look forward to your visit.

Online

Admissions

Our application process takes just a few minutes to complete, but we want to make sure you have the things you’ll need on hand to complete the application. We’re here to help if you have any questions!

Admissions Process

Your admissions application can be submitted online with your $25.00 non-refundable application fee and takes just a few minutes to complete.

- Submit a completed application and application fee.

- Submit official high school transcript, GED transcript, or official college transcripts, if applicable.

- Submit official entrance score on a validated assessment instrument, if applicable. Visit the OFTC Catalog Program Page to view each individual program and its required minimum scores.

- Complete the FAFSA (Free Application for Federal Student Aid) and HOPE applications online using OFTC School Code: 031555.

NOTE: The College may accept transfer credit for other courses according to the College’s transfer policy.

General Requirements

Be at least 16 years of age.

Additional admissions requirements unique to each program are listed on each individual program page in the OFTC Catalog.

Need More Info?

For more information about any of these programs, contact a program advisor:

Sandersville Program Advisor

Dublin Program Advisor

Louisville Program Advisor

For additional information on admission to OFTC, contact the Office of Admissions:

Sandersville Office of Admissions

Dublin Office of Admissions

Learning Format

Students can enter a Welding and Joining Technology program any semester — because when you’re ready to start on your path towards a new career and change your life, there’s no reason to wait.

Classes are offered in a variety of formats: on campus, blended, online asynchronous, and synchronous technology.

On Campus

These are courses that are taught primarily in the classroom or lab with less than 50% of instruction online. On campus courses may include lecture, labs, internships, clinicals, and other in-person instructional modalities.

Blended

Blended courses are distance learning courses with the majority of the course content, activities, and interactions occurring online but may require students to come to campus for specific assignments, activities, or events.

Online Asynchronous

These are courses that are taught fully online asynchronously with course content, activities, and interactions occurring entirely online. This delivery method does not require students to be online at a specific date or time, and students may participate in class activities and complete course assignments asynchronously. Online asynchronous courses require proctored events.

Synchronous Technology

OFTC also utilizes synchronous technology to offer courses via distance education means. The course is taught on one campus and then broadcast simultaneously to a classroom on a different campus that is monitored by a class proctor.

Flexible Schedule

We want you to get the most out of college and understand the pressure it adds to your life. At OFTC you can achieve your career goals and fit college into your lifestyle. We offer small class sizes and flexible scheduling.

Courses for our programs are offered during the morning, afternoon, and evenings – plus many are online where you can do your work any time of day.

And the personalized hands-on attention you receive in a small classroom setting allows you to get individualized support, focus and feedback from your instructors. Your instructors will get to know you and help you build the foundation and confidence needed for success in your field.

Apply TodayPaying for College

At OFTC, we realize that many students require financial assistance to achieve their academic goals. We’ll work with you to help you obtain financial aid to assist you in funding your education. We’re committed to helping you find ways to pay for this life-changing investment.

With the Pell Grant, Georgia’s HOPE Grant, HOPE Scholarship, and HOPE Career Grant (for students/programs who qualify) and other scholarship opportunities, many students graduate OFTC with little to no debt.

Financial Aid

OFTC offers several financial aid opportunities that can help you pay for college. Most students apply for federal and state aid, including the Pell Grant, HOPE Scholarship & Grant, and HOPE Career Grant.

OFTC students can also apply for scholarships through the OFTC Foundation and various businesses and civic-sponsored organizations.

Contact the Office of Financial Aid or visit OFTC’s Financial Aid web page to learn more about grants, scholarships and Federal Work Study to help fund your education.

Sandersville

Dublin

Georgia awarded over $934 million in scholarships in AY24

of OFTC students have some form of scholarship in AY24

OFTC students received over $8.4 million in financial assistance in FY25

More than 75% of OFTC students received some sort of Financial Aid in AY24

Contact

Sandersville

Dublin

Tuition & Fees

With tuition at $107 per credit hour, total costs for Welding & Joining Technology department programs range from:

- Tuition & Fees*: $1,532.00 – $7,043.00

- Books & Supplies*: $100.00 – $500.00

New Price Calculator

You can also use the Net Price Calculator to get estimated net price information based on what similar students paid in a previous year.

Career Outlook

Employers need skilled welders, so these positions offer strong earning potential, career growth, and opportunities to work on important projects worldwide.

BLS.GOV

Welders, cutters, Solderers, and Brazers

- 2024 Median Annual Pay: $51,000

- Job Outlook: 2% through 2033

What does this mean to you?

Welding is a vital, in-demand career in industry and construction. Advances in manufacturing and automation mean skilled welders are highly sought after, offering job security, career growth, and a promising future.

Learn More

job placement rate for OFTC graduates within the graduation year (AY23)

in-field job placement rate for OFTC graduates within the graduation year (AY23)

of OFTC students enrolled are First Generation college students (AY24)

Program Benefits

Skills Learned

- Read and interpret blueprints, sketches, and specifications

- Calculate and measure the dimensions of parts to be welded

- Inspect structures or materials to be welded

- Weld materials according to blueprint specifications

- Monitor the welding process and adjust heat as necessary

- Maintain equipment and machinery

Job Titles

- Welder

- Assembler and fabricator

- Sheet Metal Worker

- Pipefitter

- Metal Worker

Diverse Settings

- Manufacturing

- Construction

- Agriculture

- Specialty trade contractors

- Self-employed workers

- Repair and maintenance

"Welding can be a very lucrative career but requires a lot of time, discipline and consistency. Professional welders have skills and knowledge that only 1 % of the population have, which is why welders will always be in demand and needed. We offer welding courses for 4 of the most common welding processes used in the industry (Gas Tungsten Arc Welding, Shielded Metal arc Welding, Gas Metal Arc Welding and Flux Core Arc Welding)."